By WIll Norton

Here’s the dream behind this project: Have a wireless temperature logger that can be placed in a compost pile, whether it be a classic home compost pile, a large industrial or agricultural compost pile, or possibly a rotating compost tumbler. Such a sensor set up could be a useful tool in a classroom to integrate practical everyday applications to data lessons, or be useful to improving personal or school composting systems.

Someone out in the vast world of the internet may sell exactly this, but it probably isn’t affordable for these home and classroom applications. So we turn to the resources we have close at hand at WMSI: a Walmart and a 3D printer, to try to make our own custom design. We found a $10 wireless indoor/outdoor thermometer at Walmart to do our temperature sensing.

Unfortunately the housing for the sensor we want to put in the compost has nothing resembling water-proofing, so the design work starts with building a new compost-proof case for the temperature sensor that others can easily recreate with a 3D printer and other common inexpensive materials.

So far I’ve designed a couple of different prototypes for this sensor case.

Prototype I

Prototype II

Three problems with the first Prototype that I found were:

The case does not have a strong enough attachment point between the top and bottom to stay together

There was no way to attach the case to anything, in order to later retrieve it from compost

The sensor had a dramatically slower response to temperature in Prototype I than in other close-at-hand containers such as a Tupperware container or Ziploc bag, as shown in Fig. 1

To address the first two problems, I added larger ridges around the top of the main case, larger grooves in the lid and a loop to tie a retrieval string to. I also left an open space for a metal junction box cover I found at a hardware store, hoping to give the case a side that would conduct temperature changes to the sensor better than the plain plastic case. The results from this test are shown in Fig. 2. As it turned out, the metal cover did not make a significant difference in the responsiveness of the case, so it is probably a feature I can leave out in future redesigns to simplify the construction.

This case also needs to be waterproof in order to avoid having gross compost juices leak onto the temperature sensor and ruin it. I tested the second prototype for waterproofing in three ways to see where, if anywhere, it would leak:

I placed it open on a paper towel and filled each half of the case with water

I placed a paper towel into the case and closed it and floated it in a bowl of water

I filled the case with water and closed it and rolled it around to see where water came out

The result in all three experiments was:

Clearly waterproofing is something that needs more work. The largest leak by far seemed to be the connection between the plastic lid and the base, but water also leaked through the seemingly solid plastic of the case. Some solutions to explore in the future include different types of plastic for the printer, coating that would waterproof the plastic, and some sort of gasket for the meeting of the two plastic pieces.

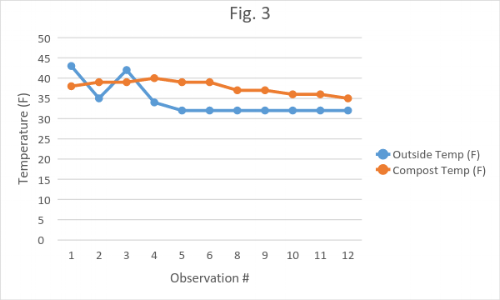

Not to be outdone by a small flood of water leaking into my case, I put the sensor in a plastic freezer bag and put the setup in my home compost pile to get some temperature data and see if the sensor could broadcast through a pile of rotting food. The results are in the below table and Fig. 3.

*Other thermometers showed significantly lower temperatures.

The data shows a slight downward trend in the compost temperature as the weather got colder over the 6 days I collected data. However, more interesting than the actual numbers are two limitations of our sensor that I found. First of all, the indoor temperature sensor on the unit with the display which I used to measure the outdoor temperature seems unable to read below 32 degrees, since according to other thermometers the temperature was well below 32 after the seventh reading on the afternoon of March 3rd. The second limitation is that about half the time when I went to collect data, the display had lost wireless contact with the thermometer and had to be reset by removing and reinserting the battery, and in one instance was unable to reestablish contact for several minutes before I had to leave. It’s unclear what caused the loss of contact; possibilities include the compost interfering with the signal, or cold temperatures decreasing the charge of the batteries.

The takeaway from this experiment is that it is indeed possible to make a functional compost-proof case for a wireless thermometer for a small compost pile using 3D printing and easily available supplies. This setup worked just well enough for this simple experiment, but the unreliability of the signal would make it unhelpful in any sort of data logging setup. The case has some flaws such as not being waterproof on its own, and having a flimsy recovery system that wouldn’t help in a larger compost pile such as on a farm. With more redesign and research, these design obstacles may be overcome, and with more experimentation the cause for the signal loss could be isolated and removed if the cause is not the dense compost interfering with the signal. If, however, the signal loss is caused by the compost, that may become an insurmountable obstacle.